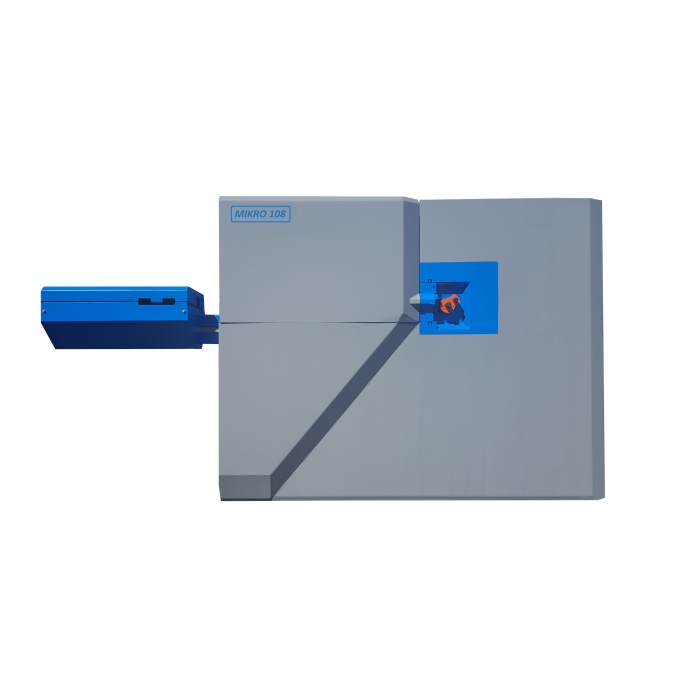

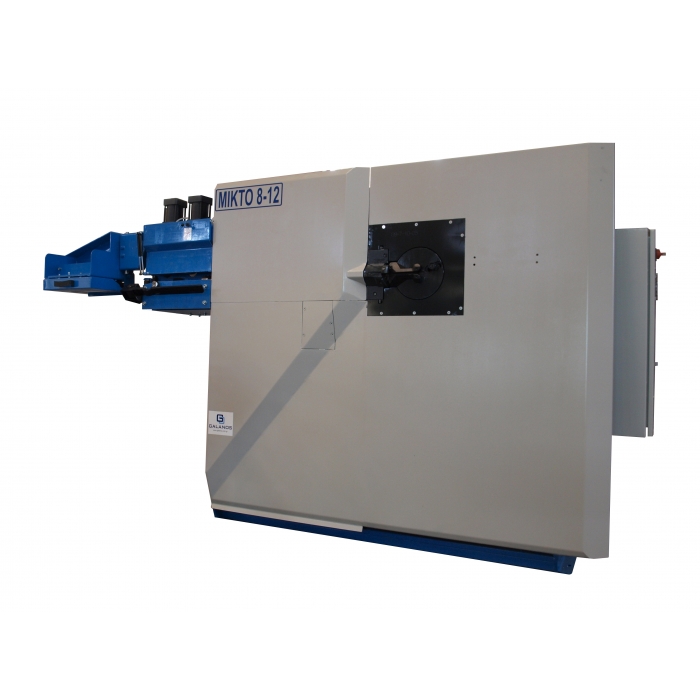

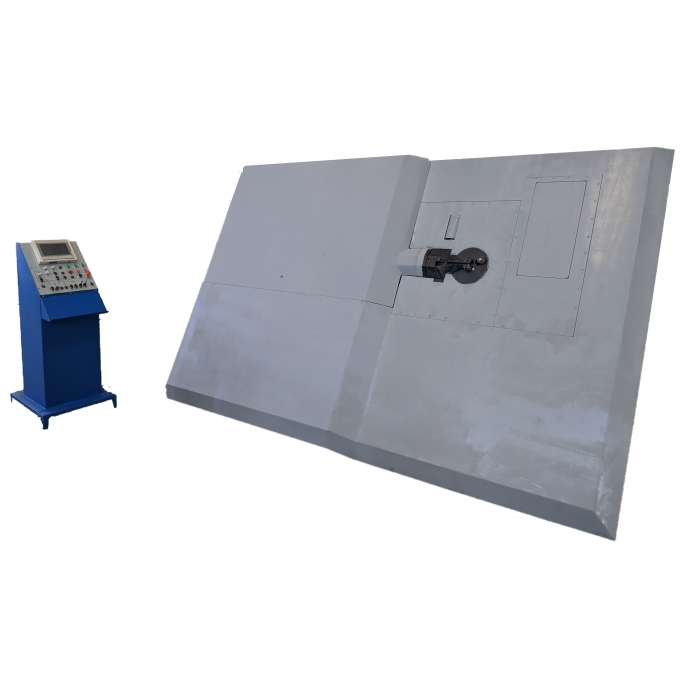

MIKRO 10

|

Automatic forming machine from coil, uni-directional, programmable, CNC, designed for the production of common stirrups as well as the re-bar bending.

*”GALANOS SA” can modify the above-mentioned data without previous warning*

MIKRO 10 is provided with main and auxiliary mechanisms necessary for the function; Α) Main mechanisms: 1. Propulsion System 2. Straightening system 3. Bending system 4. Cutting system 5. Control panel 6. Electro-logical board

B) Auxiliary mechanisms (additional equipment upon request): 1. Pay off for the support of structural steel coil

Α.1. Propulsion System The Propulsion System consists of four rollers. Two moving rolls (servo electric powered) and two free ones. An encoder is moved by the free roller.

Α.2. Straightening system

The straightening system consists of two groups of rolls, each other reversed. This way, the operator achieves the complete straightening of the rod on both planes (up-down and right-left). In the specific system, there are immovable and movable rolls. The movable ones, move upwards-downwards manually. Thus, the interchange of the rod diameter as well as the regulations for the straightening towards all directions is achieved.

Α.3. Bending system

The bending system is provided with a rotating disk that rotates in one direction via servo-motor. On the disk, a side bending pin is placed, which has the ability either to move towards the centre of the disk or to move back towards the periphery of the disk, depending on the diameter of the rod to be elaborated. At the centre of the disk, the immovable formation part is placed.

Α.4. Cutting system The cutting system is hydraulic powered and carries out lateral cutting, while the cutting plates bear with two shearing sights

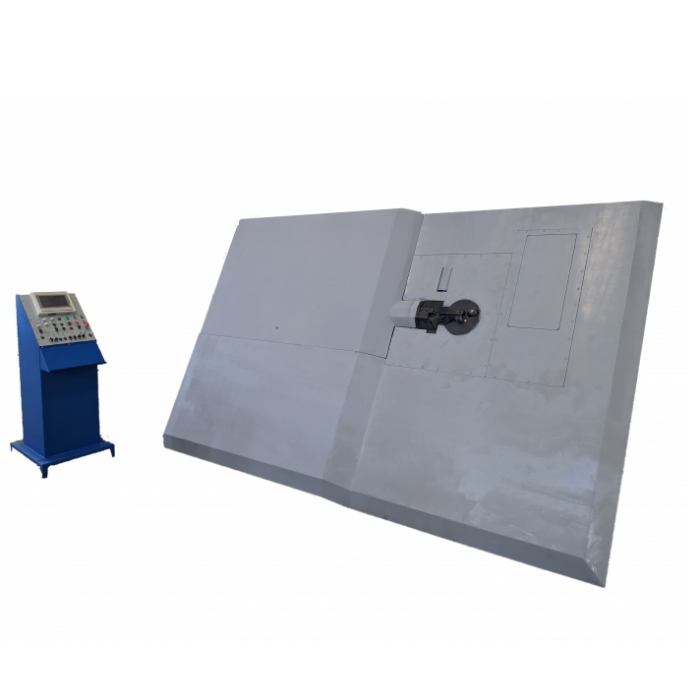

A.5. Control panel

The control panel is placed next to the machine and at its inner part there is an industrial PC. At the front view of the control panel, are adjusted the buttons for manual commands, and the touch screen. During programming phase, at the screen is developed the figure exactly as it will be executed during production procedure and the operator can select its storage directly in the computer’s memory in case he wishes to recall it for future production execution. Moreover, additional data are indicated at the screen, which the operator can see within bounds of daily production, such as: – Total rod length for each figure – Total quantity (No of pieces) to be produced – Total weight of pieces – Produced shapes (pieces) – Produced shapes (Kg) – Remaining pieces (to be executed) – Rod diameter – Function indication for option of production by use of single/double wire

Programming ways

a) via screen b) by use of USB memory stick c) recall directly from computer’s memory

Α.6. Electro-logical board All electric/electronic components are supplied by EMERSON, SCHNEIDER, WEINTEK, PHOENIX

Α.7. Hydraulic unit The hydraulic unit bears with one pump of special construction (proper to such type of machinery), one pre-heater as well as an air-cooled oil system. All components of the hydraulic unit are supplied by “VICKERS” and “YUKEN”.

Shapes:

?Together with the main equipment, «GALANOS SA» delivers to the client a tools collection, as well as some consumable spare parts. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||